Vespel is the trademark of a range of durable high-performance polyimide-based plastics manufactured by DuPont.Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. The best known brand name of PTFE-based formulas is polymer by Chemours . Chemours is a spin-off of DuPont Co., which discovered the compound in 1938.

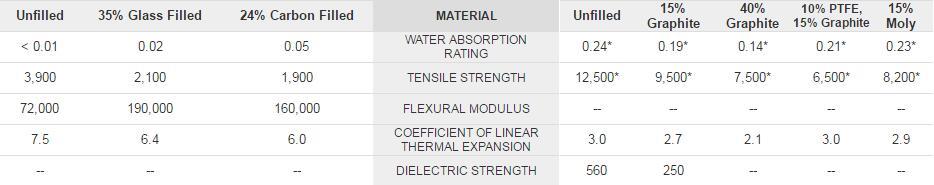

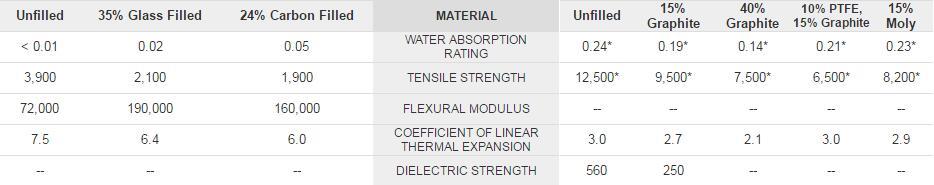

Comparison of Polymer PTFE/FEP and Vespel Property Values

Material Applications

Polymer PTFE/FEP:Cabling solutions;Non lubricated bearings;O-rings;Seals;Capacitors;Semiconductor manufacturing;High temperature electrical parts;Gaskets;Valve components.

Vespel:This high performance polymer is mostly used in aerospace, semiconductor and transportation technology. It combines heat resistance, lubricity, dimensional stability, chemical resistance, and creep resistance, to be used in hostile and extreme environmental conditions.Unlike most plastics, it does not produce significant outgassing even at high temperatures, which makes it useful for lightweight heat shields and crucible support. It also performs well in vacuum applications, down to extremely low cryogenic temperatures. However, Vespel tends to absorb a small amount of water, resulting in longer pump time while placed in a vacuum.

Material Properties

Polymer PTFE/FEP:Excellent dielectric properties;Inertness to most chemicals;High heat and chemical resistance;Very low coeffiecient of friction;Excellent radiation resistance;Zero moisture absorption;Relatively insensitive to power frequency;Machinability.

Vespel:Continuous performance at up to 600°F;No special machining equipment required;Dimensionally stable;Operates at very high PVs;Does not become brittle even at subzero temperatures;Machinability.

Post time: Jul-04-2018